Newest

-

Dongying Builds China's Leading Public Testing and Certification Platform for Offshore Wind Power Industry

-

Hefei Spring Festival Gala Sub-Venue: Understanding the City’s “Union” Through Four Moments of Palms Meeting

-

Musician Dai Yutong Finds Inspiration in Ancient Xun County: 'True Art Stems from Deepest Roots'

-

MEXC Releases February Proof of Reserve Report, BTC Coverage Rises to 267%

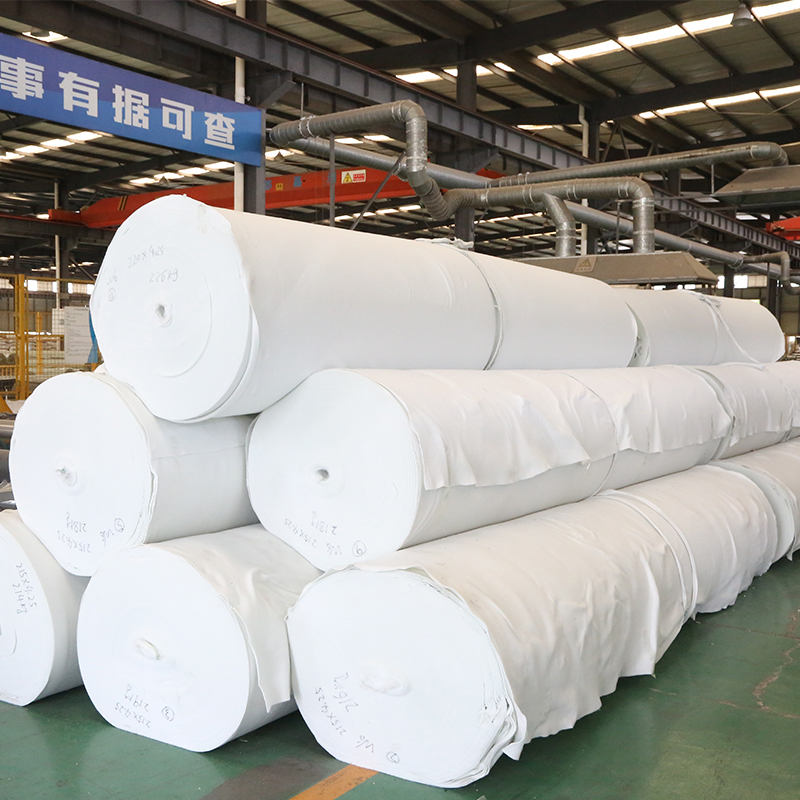

Non-woven Geotextile

2022-08-05

2022-08-05

Non-woven geotextile is a kind of geotextile with three-dimensional porosity structure, which is generally called non-proof cloth. Non-woven geotextiles are divided into short filament geotextiles and filament geotextiles, commonly known as polyester filament fabrics and staple filament fabrics. Polyester silk cloth should be made of newly upgraded polyester chips as raw material, melted and melted at high temperature, punched into a mesh, and needled into soil; Rolling, laying 4 to 5 layers of mesh, followed by laser cutting and edge forming of the soil through the four-stage needle piercing process of pre-thorn, barb thorn, and main thorn.

Composite geomembrane is a composite geosynthetic material composed of non-woven geotextile and other sheets. This type of sheet is usually an impermeable geomembrane, with a thickness of more than 1mm. People habitually call the geomembrane a waterproof board.

Anti-seepage geomembrane is a high polymer material with high-quality waterproof layer characteristics. Therefore, composite geomembrane refers to a waterproof geotextile formed by a composite of cloth and membrane, commonly known as composite membrane. One-cloth-one-membrane and two-cloth-one-membrane composite membranes are the most common, because the cloth maintains the membrane in the middle, so that the geomembrane is not cracked by hard block puncture or due to arc foundation settlement, and its waterproof layer The actual effect is longer and more stable.

The difference between non-woven geotextile and composite geomembrane

Non-woven geotextiles have the characteristics of water permeability, reinforced safety protection and anti-filtration. The two are just the opposite. Composite geomembrane (waterproof geotextile) has excellent waterproof layer and protective characteristics. Therefore, many large and medium-sized engineering projects must cooperate with each other to form the main system software of waterproof layer. Usually, the waterproof layer system is divided into a single-sided gasket layer and a waterproof layer or two or even multiple layers, which is determined according to the design concept. With the increasing attention paid to the natural environment, environmental protection technology is increasing day by day. Because the two have the advantages of low cost, convenient transportation, simple construction and short construction period, they are very suitable for various environmental protection projects and can save project budgets. Therefore, Both have irreplaceable effects.

Non-woven geotextiles are made of polypropylene, polyester, taslon and other man-made fibers as raw materials, and have high initial super strength. After weaving, it forms a regular staggered structure, and the comprehensive bearing capacity is improved in an all-round way. A geosynthetic material produced by integrating various characteristics and regulations of geological engineering.

Application of non-woven geotextile:

It is used in geological engineering such as rivers, bays, seaports, roads, railway lines, ports, tunnel construction, highways and bridges. A variety of different main uses can be considered.

Non-woven geotextile characteristics:

1. High tenacity: High tenacity industrial grade polypropylene cloth, polyester cloth, Taslan and other man-made fibers are used as raw materials, which have high initial strength. After weaving, it forms a regular staggered structure, and the comprehensive bearing capacity is improved in an all-round way.

2. Use performance: The characteristics of chemical fibers are that they are not easy to be denatured, dissolved, and weathered. It can maintain its original characteristics for a long time.

3. Corrosion resistance: The generated chemical fibers usually have acid resistance, alkali resistance, insect resistance, and Aspergillus flavus resistance.

4. Water absorption: The woven fabric can reasonably manipulate its structural porosity to exceed the necessary water absorption.

5. Convenient storage and transportation: Because it is very light and can be packaged according to necessary regulations, it is very convenient for transportation, storage and engineering construction.

Non-woven geotextile function:

1. Using the excellent air permeability and water absorption of non-woven geotextiles, the flow of water is based on the ground, and then the outflow of gravel and soil is reasonably intercepted.

2. Non-woven geotextile has excellent water-conducting properties, it can create a safe channel for drainage pipes inside the sandy soil, and discharge unnecessary liquids and vapors in the sandy soil structure.

3. Use non-woven geotextiles to improve the compressive strength and deformation resistance of sand, improve the reliability of building structures, and improve the quality of sand

4. Reasonably spread, transmit or dissolve the concentrated ground stress to avoid the damage of sandy soil by external force.

5. Avoid mixing between the upper and lower layers of sand, sand and concrete.

6. The pore ring is not easy to block - the porous structure produced by the mud-loaded connective tissue has strain rate and autonomous movement.

7. High water absorption - can maintain stable water absorption under the working pressure of soil and water

8. Anti-corrosion - chemical fibers such as polypropylene cloth or polyester cloth are used as raw materials, which are resistant to corrosion, corrosion, insects, and oxidation.

9. Simple engineering construction - very light, easy to use, simple engineering construction

Common problems of non-woven geotextile engineering construction

1. It is necessary to minimize the turning or sudden braking of the car on the non-woven geotextile, especially when the asphalt concrete cushion is constructed on the road.

2. Applying under the climatic standard of rainy days, wet and cold or severe cold will harm the bonding compressive strength of the coating and the actual effect of the elastic coating.

3. Traffic must be closed during the paving process. Except for construction vehicles, other vehicles can only be allowed to pass on the non-woven geotextile in emergency situations.

4. If the asphalt paver deviates during the construction of hot mix asphalt concrete on the road surface, a small amount of stone can be sprinkled on the oil surface of the sticky layer.

Sichuan Zhijia New Material Co., Ltd. was established in 2020. It is a professional waterproof technology comprehensive enterprise integrating scientific research, production, sales, construction and after-sales. The company's products are widely used in railways, highways, subways, airports and other rail transportation fields. ; Landfills, tailings, artificial lakes, sewage treatment tanks, civil air defense and other anti-seepage fields;

our products:

Polymer material series: PE, EVA, ECB waterproofing board, single (double) surface composite waterproofing membrane, point type composite waterproofing membrane, strip type composite waterproofing membrane, self-adhesive waterproofing membrane;

Geotextile series: 8m wide staple fiber needle-punched non-woven geotextile, filament spunbond needle-punched geotextile, 8m wide smooth geomembrane (HDPE/MDPE/PE/LLDPE), 8m wide rough surface geomembrane, 8m wide composite geomembrane;

Coating series: polyurethane waterproof coating, JS waterproof coating, cement-based permeable crystalline coating, plugging agent, etc.;

New material series: acrylate spray membrane waterproof material;

Other series: geogrid, geocell, corrugated pipe, blind ditch, three-dimensional geonet pad, composite drainage board, etc.

Our advantages: Our technical team: We have more than 10 professional core technicians who have been deeply involved in the waterproof industry for more than 10 years. From product research and development, materials, process technology, production control, inspection and testing, we form a complete control of the entire product process. system.

Our testing system: We are the only manufacturer with a complete product testing system in the waterproof industry in the western region;

Our services: We can provide customers with professional technical solutions before sales and professional construction technical guidance after sales.

Our aim: to provide customers with the most cost-effective products and professional systematic solutions.

Mr Yao

295193121@qq.com