Newest

-

Dongying Builds China's Leading Public Testing and Certification Platform for Offshore Wind Power Industry

-

Hefei Spring Festival Gala Sub-Venue: Understanding the City’s “Union” Through Four Moments of Palms Meeting

-

Musician Dai Yutong Finds Inspiration in Ancient Xun County: 'True Art Stems from Deepest Roots'

-

MEXC Releases February Proof of Reserve Report, BTC Coverage Rises to 267%

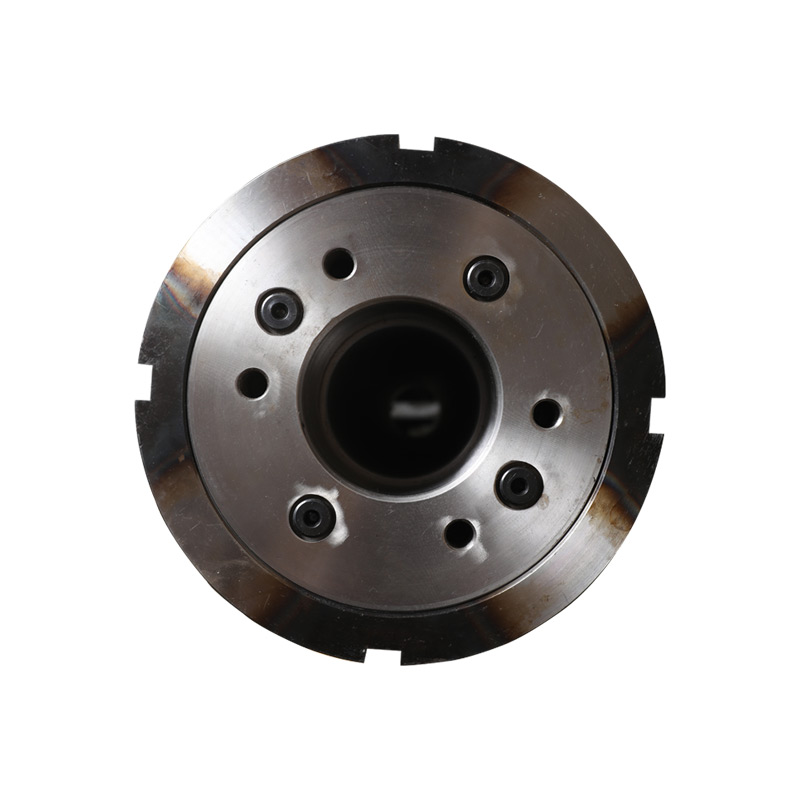

PRINCIPAL AXIS

2022-10-19

2022-10-19

Spindle refers to the shaft that receives power from the engine or motor and transmits it to other parts. The main axis, also known as the "optical axis", is the abbreviation of the "main optical axis": the diameter with symmetry in the optical set. For example, the main axis of a spherical mirror is a straight line perpendicular to the mirror surface through the center of the mirror surface. The main axis of the lens or optical axis optical device group is the connecting line of the center of each mirror surface.

The main shaft is equipped with a rotating part of the fan, which is used to transmit torque to make the impeller rotate. The main function of the main shaft is to transmit torque. The main shaft, together with other parts of the bearing and rotor part, becomes the main shaft part, mainly the rotor part of the machine. Different main shaft parts have different functions. For example, the steam turbine mainly absorbs steam energy to drive the generator set to generate electricity. The super organic main shaft drives the piston to output power, and the main shaft of the water pump drives the impeller to produce pressure to transport water and other media.

Spindle is a typical shaft part, which is one of the key parts of the equipment. It transfers the whirling motion and torque to the equipment through the end of the spindle. Therefore, the spindle must bear the torque and bending moment in the work, and also requires a high rotation accuracy. Therefore, the manufacturing quality of the spindle will directly affect the service life of the whole equipment. The spindle part drawing specifies a series of technical requirements, such as dimensional accuracy, shape and position tolerance, surface roughness, contact accuracy and heat treatment requirements. These are to ensure that the spindle has high rotary accuracy and stiffness, good wear resistance and dimensional stability.

Chengdu Haihe Power Equipment Accessories Industrial Co., Ltd. was established in 2002, formerly known as Chengdu Feixuan Ventilating Machinery Development Co., Ltd. (Chengdu Power Machinery Factory is one of the shareholders). The company is mainly engaged in surveying, mapping, designing and producing auxiliary machines, complete machines, spare parts for power plants, such as fans, ventilation ducts, pulverizers, reducers, and their on-site installation and commissioning, as well as mapping, design and production of various types of structural parts. The company has more than 40 employees, including 2 senior engineers, 4 technicians, 3 engineers, 12 riveters, 9 welding application technicians and 9 turning technicians. Each employee has excellent skills. Through continuous technical transformation, the plant has the ability and experience to design and manufacture various centrifugal induced draft fans, forced draft fans, primary fans, secondary fans, powder exhaust fans, ball mills, gear reducers, slag crushers and coal grab hoppers for 200MW to 1000MW thermal power units.

The company has abundant funds, excellent technical force and complete production equipment. It can undertake the mapping design and production of various riveting and welding structural parts and machined parts. The company has excellent processing equipment, advanced production technology, complete detection means and perfect management measures. It has laid a solid foundation for developing first-class products and providing first-class services. We are willing to sincerely cooperate with friends from all walks of life for mutual benefit and create the future together.

Chen Tao

453620554@qq.com