Newest

-

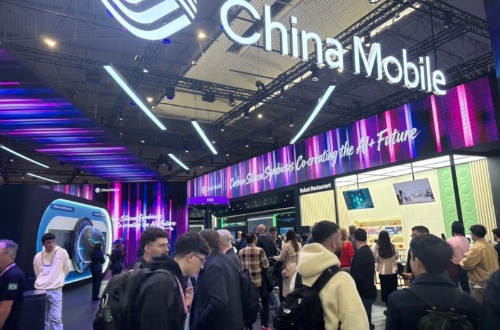

Inside MWC 2026: See How China Mobile Leads the Tech Innovation Wave

-

China Eastern Airlines Announces Comprehensive Upgrade to International Route Network in 2026

-

SOUEAST S08 DM Pre-sale Opens in the UAE:"Motorsuite" Redefines Quality Travel

-

iCAUR Makes Strategic Entry into the Middle East: Announcing V27's Global Launch in UAE

What is low pressure injection molding process and what are the benefits

2020-10-13

2020-10-13

What is low pressure injection molding process?

Low pressure injection molding (LPM) is different from traditional injection molding. Low pressure injection molding is where parts are molded under lower pressure, allowing gentle packaging of precision electronic components. The secondary molding process involves loading the bare, unprotected PCB and cable assembly into a precision-made moldset tool, and then filling the cavity with appropriate low-pressure molding materials. This effectively encloses the components in the desired shape, producing a sealed and protected product that can be processed and tested immediately. The LPM process is very suitable to replace the epoxy potting process to save cycle time and reduce material consumption.

What are the benefits of low pressure molding?

The processing temperature and pressure required by traditional injection molding materials can damage printed circuit boards. Low-pressure molding (LPM) uses thermoplastic materials with very low viscosity, allowing even the most sensitive circuit board components to be re-molded and packaged. Because this material is a natural adhesive, this process is very suitable for sealing circuits against dust and moisture. The low-pressure injection molding process is very suitable for encapsulating precision instruments, such as circuit boards, data lines, automotive electronics, and sensors. , Micro switches, inductors, antennas and other precision components.